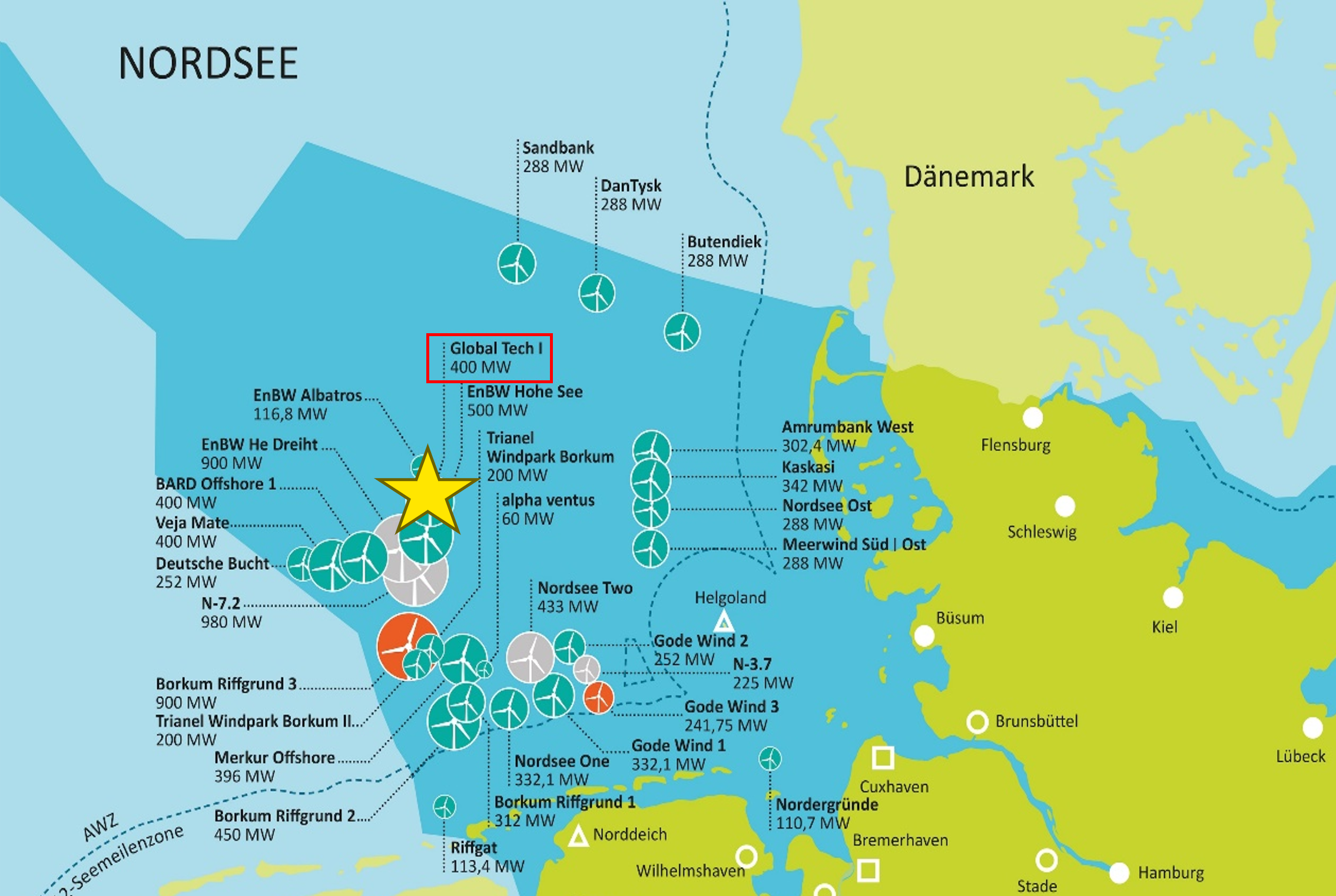

The project pipeline

10 MW Demonstrator (OWF Global Tech I)

Source: Stiftung Offshore Windenergie

Desalination and electrolysis are carried out on a H2-production platform, mounted on top of a bottom-fixed foundation. All components are tested for production, storage, and re-electrification. Input data is provided for research projects, aiming to achieve proof of concept by 2028.

300 MW Pre-Commercial Project (European OWF area)

Source: 4C-Offshore

The project involves a 300 MW production platform. H2-transport will be facilitated either via pipeline or ship. The technical concept will be developed further under a funding regime.

Step 3

> 1 GW Scale (globally applicable)

Source: Global Wind Atlas

The project involves a 300 MW production platform. H2-transport will be facilitated either via pipeline or ship. The technical concept will be developed further under a funding regime.

10 MW Demonstrator: Global Tech I

We are developing a demonstration project to validate the feasibility of hydrogen production under challenging offshore conditions. With an installed electrolysis capacity of 2×5 MW, the project is integrated into Global Tech I, one of Germany’s commercial offshore wind farms. It leverages the existing foundation and operational setup to minimize additional infrastructure requirements. The initiative also features a self-sufficient research platform designed to test all critical technical components, including desalination, electrolysis, hydrogen storage, and re-electrification processes.

LoI to jointly develop the H2-Demo-Project was signed on 13th October 2025 between:

What we want to achieve:

- A proof of concept for offshore electrolysis

- Performance data of Electrolysis process coupled with fluctuating renewable energy

- Compatibility assessment of auxiliary equipment such as compressor and desalination plant with electrolysers under fluctuating electricity and offshore environment

- Investigation of hydrogen intermediate storage and re-electrification for emergency power supply with the produced hydrogen

- Visibility for all involved partners (research institutions, regulatory bodies, industry, finance, insurance)

Our 300/1000 MW Platform concept

What we want to achieve:

- Production of up to 70,000t of green hydrogen per year at an industrialized level

- Highest level of redundancy and security against foreign influence

- Green Hydrogen “Made Localy”

The H2 Production flow

Storage and offshore handling

A Double Anchor Loading (DAL) system enables the efficient offloading of hydrogen to shuttle tankers. Additionally, the platform includes an offshore refueling station for hydrogen-powered Service Operation Vessels (SOVs) and Crew Transfer Vessels (CTVs), supporting sustainable maritime operations.

Transport solutions

Pipeline

- Germany: AquaDuctus – directly connected to German H2 Core-Network via Wilhelmshaven

- Gaseous transport of H2 @ 100bar

Vessel

- Vessel dimensions (L x W): 215 m x 32 m

100 % Hydrogen energy supply/zero emission - Highest automation level

- H2 transport capacity: 500 tons @ 250 bar

Development team

- Developed and realized the “HY.City.Bremerhaven” H2-fueling station

- Strong and wide personal network

- Practical H2 experience

- Project development

- Technical project mana-gement for offshore wind, hydrogen and marine infrastructure projects

- Project development & construction; Technical Experts & Advisors

- Full-Service Ship Management / Vessel owning and brokerage / Offshore Living Quarters

- Transport & Installation / Decommissioning / Offshore Support

- Special Maritime Transportation / Salvage / Deep-Sea-Technology Development

Development timeline

-

2021

Conceptional design, Establishing project consortium, Networking, Discussion with politics and authorities -

2022-2023

Early project development, Approach potential investors, Discussion with offtakers -

2024

Site allocation 10 MW Demonstrator -

2024-2028

10 MW Demonstrator OWF Global Tech I:

Project Development, Fabrication, Installation, Commissioning

-

2028

10 MW Demonstrator:Operational phase, Hydrogen production, Testing and research → proof of concept

-

2028-2030

Know-how transfer to 300 MW pre-commercial project:Secure suitable sea area (auction), Project development, Permitting process, Supply agreements, Financial close

-

2030-2032

10MW-Demonstrator: Operational phase, Hydrogen production, Testing and research, Decommissioning300MW pre-commercial project: Fabrication, Installation, Commissioning

1 GW commercial project: Secure suitable sea area (auction), Project development, Permitting process, Supply agreements, Financial close

-

2033-2036

300MW pre-commercial project: Operational phase, Hydrogen production → ~20,000t H2/year1 GW commercial project: Fabrication, Installation, Commissioning

-

2036-2066

300MW pre-commercial project: Operational phase, Hydrogen production → ~20,000t H2/year1 GW commercial project: Operational phase, Hydrogen production → ~70,000t H2/year

Contact

The hydrogen future starts now!

What’s in it for you? Let’s talk!

Managing Partner

NorthH2 Projektgesellschaft mbH

Am Lunedeich 156, 27572 Bremerhaven

Cph: +49 172 754 6336

a.wellbrock@northseahydrogen.de